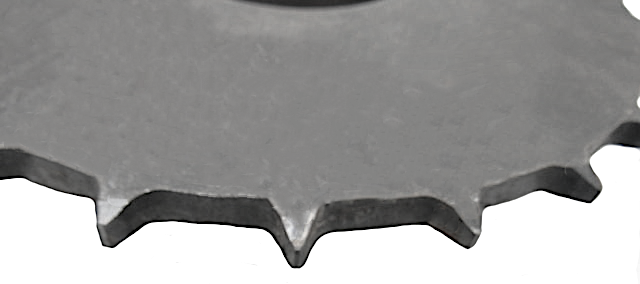

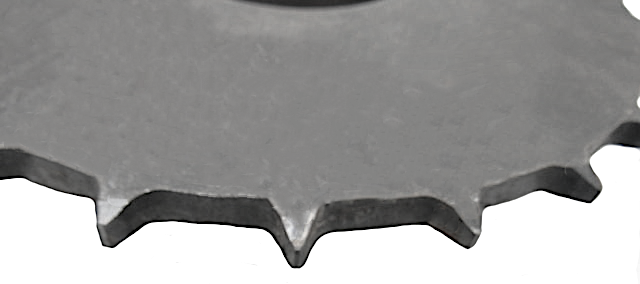

Mill Chain Sprockets

Mill chain sprockets are designed for running in some of the most rugged environments. Through years of experience in the lumber mill industry, we understand what it takes to keep a mill up and running. Our mill chain sprockets are second to none; we stock many standard mill-duty sprocket plates and can provide custom mill sprockets in as little as one business day! Ranging in welded steel chain sizes WH78 up to WDH480 along with 81X-series, cast combination, and standard large pitch roller chain sprockets, we supply the broadest range of mill chain sprockets on the market.

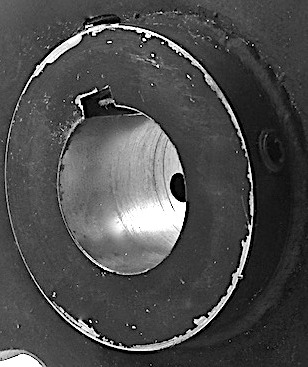

Mill Chain Sprocket Capabilities

- Split and Sectional

- Hardened Teeth

- Skip-Tooth Configuration

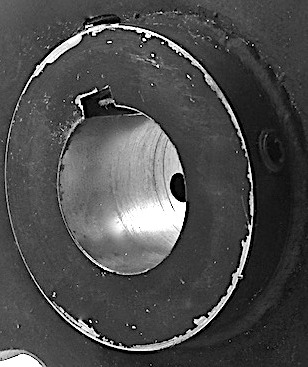

- Custom Bore Ranges

- Materials including steel, cast, and plastic

- Idler & Drive Configurations

- Shear-Pin

Welded Steel Mill Chain Sprocket Sizes

WH78 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH82 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH78-4 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH124 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH111 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH106 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH132 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

WH155 Sprockets

Welded steel chains consist of WH and WR series chains; they are constructed with a barrel welded directly to the sidebars; these chains are offset in design and are utilized in a range of mill and conveying applications.

|