Dimensions:

- Bushing Type: H

- Bore Size: 10mm

- Dimension (L): 1-1/4"

- Dimension (U): 1/4"

- Dimension (T): 1"

- Large End Dimension (D): 1.625"

- Small End Dimension (D): 1.570"

- Dimension (H): 2-1/2"

- Dimension (V): 2"

- Dimension (X): 7/8"

- Dimension (Y): 3/16"

- Dimension (R): 1/8"

- Dimension (S): 3/16"

- Cap Screws Amount: 2

- Cap Screw Size: 1/4" X 3/4"

- Wrench Torque: 95 LBS

- Weight: 0.8

Installation

2. Place the bushing in sprocket or other part type that accepts the bushing.

3. Place cap screws loosely in pull-up holes. The bushing remains loose to assure sliding fit on shaft.

4. With key on shaft, slide the sprocket or other part type to the desired position on the shaft. Be sure to leave the heads of the cap screws accessible.

5. Align the sprocket or part type, tighten the screws alternatively and progressively until they are pulled up tight. Do not use extensions on the wrench handles and do not allow the sprocket or part to be drawn i contact with flange of bushing. At this point there should be a gap between the bushing flange and sprocket, make sure this gap does not close.

2. Insert cap-screws in tapped removal holes.

3. Tighten inserted screws until sprocket or other part type is loose on shaft.

4. Remove sprocket/ part type from shaft.

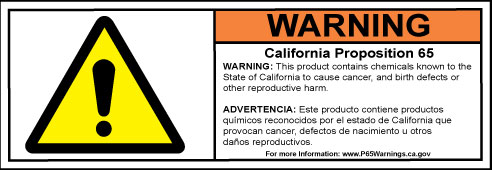

Warnings: use of anti-seize lubricant on tapered cone surfaces or on bolt threads when mounting may result in damage to sheaves and sprockets. This voids all manufacture's warranties.

Phone: (407) 347-3519

Email: sales@usarollerchain.com

See What All We Offer "Here"!

Feature

- Premium Quality Bushing

- Extremely Durable

- High-Precision Machined

- Made With High-Quality Steel

- Bushing Type: H

- Bore Size: 10mm

- Dimension (L): 1-1/4"

- Dimension (U): 1/4"

- Dimension (T): 1"

- Large End Dimension (D): 1.625"

- Small End Dimension (D): 1.570"

- Dimension (H): 2-1/2"

- Dimension (V): 2"

- Dimension (X): 7/8"

- Dimension (Y): 3/16"

- Dimension (R): 1/8"

- Dimension (S): 3/16"

- Cap Screws Amount: 2

- Cap Screw Size: 1/4" X 3/4"

- Wrench Torque: 95 LBS

- Weight: 0.8