Screw Conveyor Trough Ends

The trough end portion of a screw conveyor system is essentially an endplate that supports the screw, bearing, and seal. Also commonly offered as an endplate, trough ends are responsible for withstanding a large amount of force while the screw is in operation and this force is increased as the system is longer. Our trough ends are made from high-quality heavy-gauge steel to ensure a long-term operating life and performance. Standard trough ends that house standard shaft sizes are typically in-stock and readily available but custom made trough ends can be supplied as well.

Standard Trough End Styles

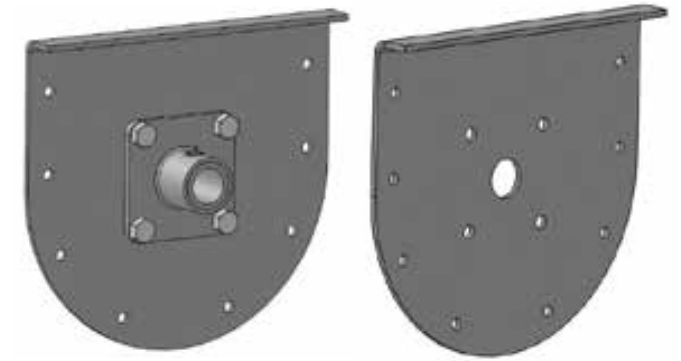

Style 100 Trough Ends:

This style of trough end is a steel plate that is typically fitted with babbitted transmission flange bearings, although any bearing material may be used. The top flange supports the cover of the conveyor so this means that the system must be supported either from above or a foot on the trough end flange.

Style 101 Trough Ends:

Style 101 trough ends are also a steel plate that is typically fitted with babbitted transmission flange bearings, although any bearing material may be used. However, with this design there is a top and bottom flange, meaning the top flange supports the screw conveyor cover while the bottom flange supports the bottom of the conveyor.

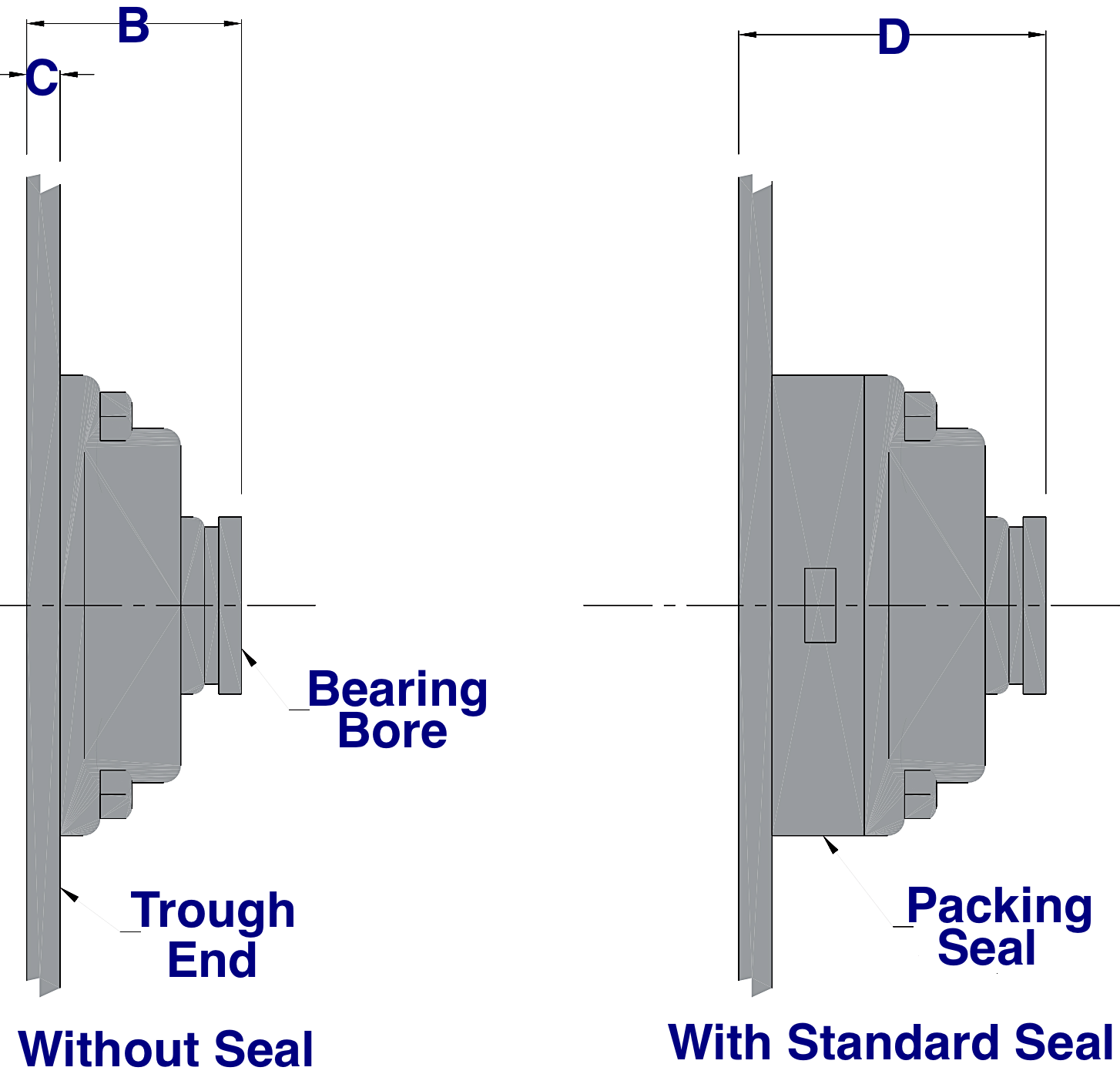

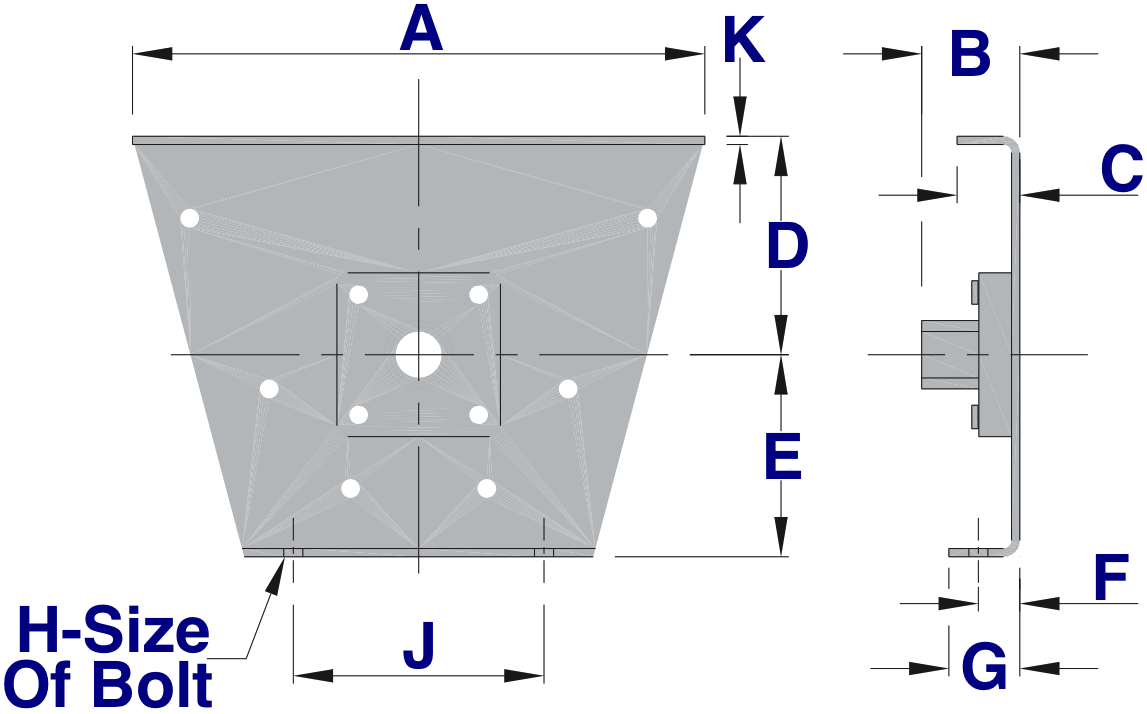

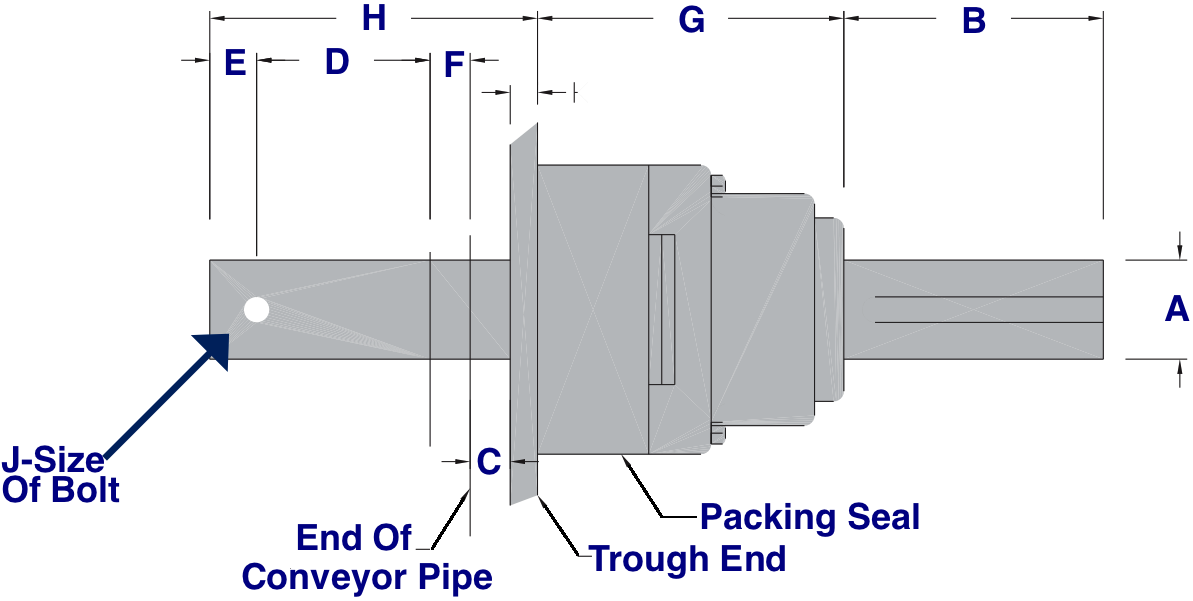

100 and 101 Trough End Dimensions

.png)

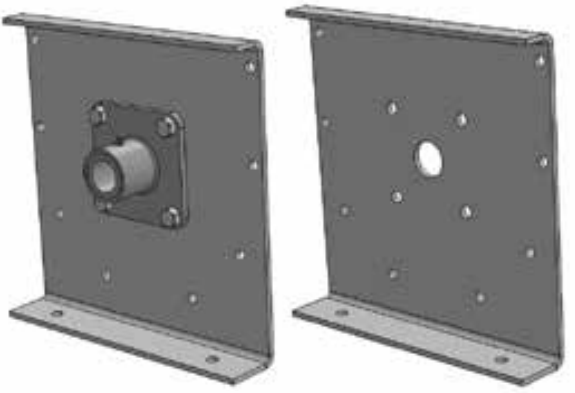

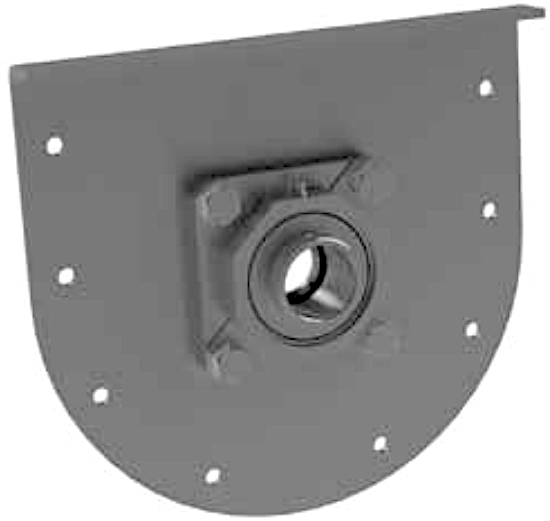

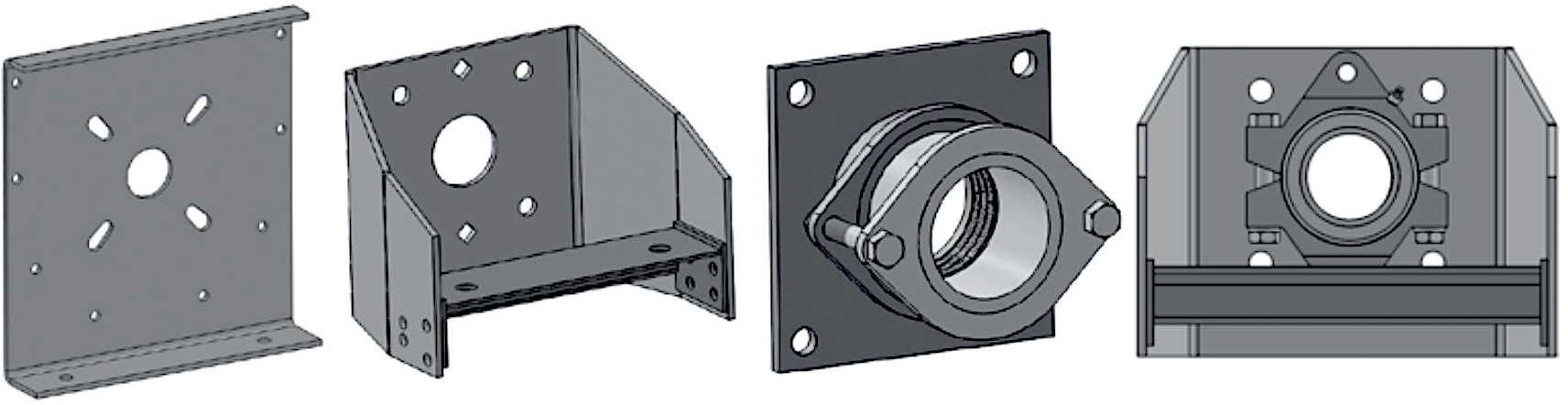

Style 102 Trough Ends:

Style 102 trough ends are considered anti-friction type because it is equipped with self-aligning ball bearings, which also allows for several degrees of end shaft misalignment. This style is not recommended for use with the drive shaft unless it is for very light-duty applications, drive shafts are usually recommended to be equipped with Chevron end thrusts or another type of rigid bearing support bearing type. The top flange supports the cover of the conveyor so this means that the system must be supported either from above or a foot on the trough end flange.

Style 103 Trough Ends:

Style 103 trough ends are also considered anti-friction type because it is equipped with self-aligning ball bearings, which also allows for several degrees of end shaft misalignment. This style is not recommended for use with the drive shaft unless it is for very light-duty applications, drive shafts are usually recommended to be equipped with Chevron end thrusts or another type of rigid bearing support bearing type. The top flange supports the cover of the conveyor so this means that the system must be supported either from above or a foot on the trough end flange. However, with this design there is a top and bottom flange, meaning the top flange supports the screw conveyor cover while the bottom flange supports the bottom of the conveyor.

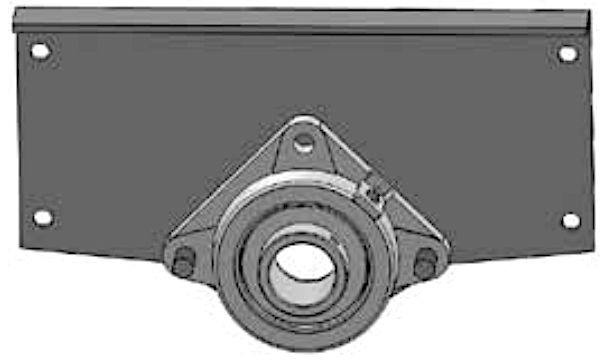

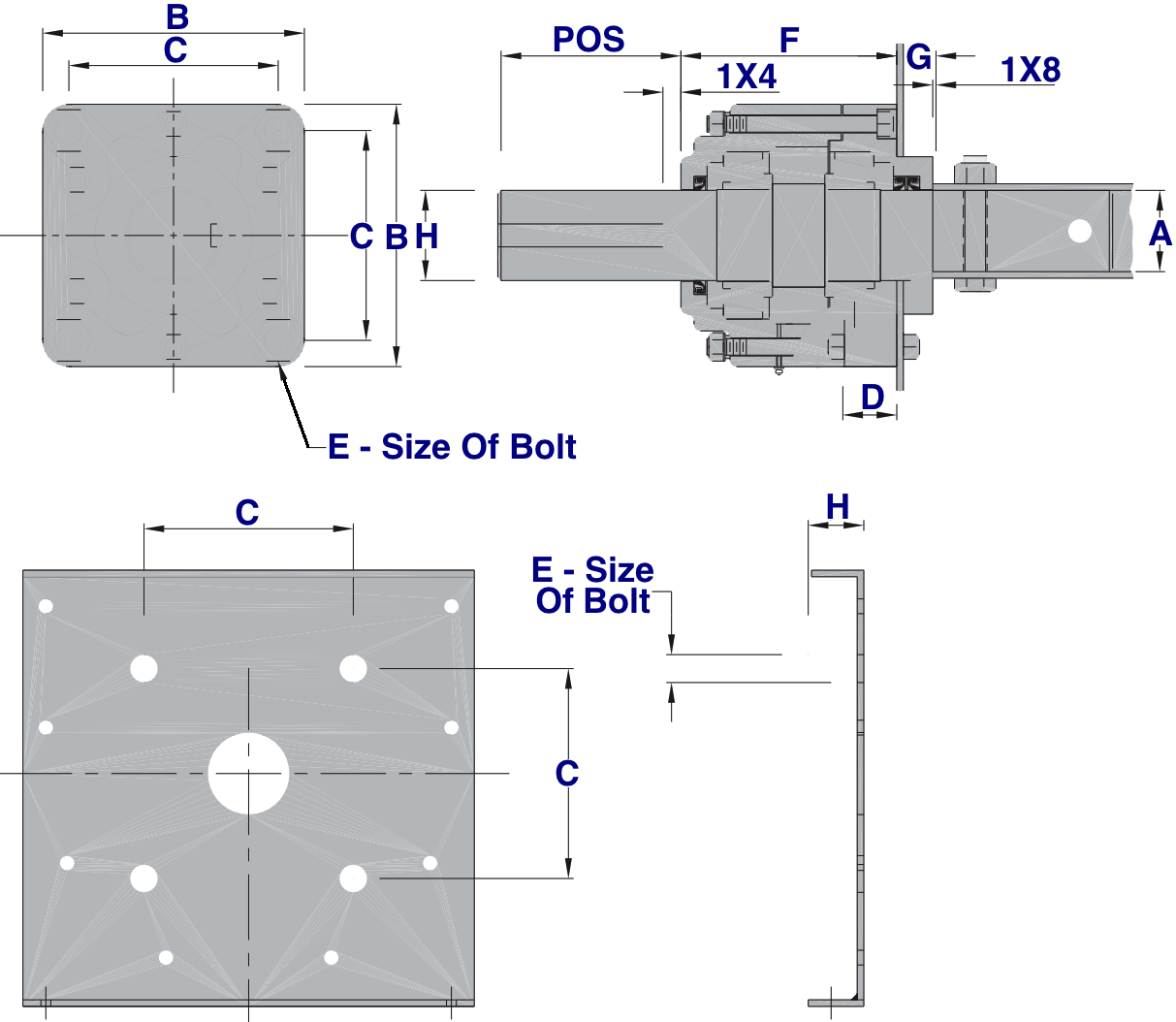

102 and 103 Trough End Dimensions

Style 104 and 107 Discharge Trough Ends:

Styles 104 and 107 trough ends are known as discharge trough ends because it is designed to be used in where the material is to flow out of the end of the trough and when the material loading does not exceed 45%. Style 104 is fitted with a self-aligning ball bearing while style 107 is typically fitted with a babbit flange bearing with the exception of two or three-bolt flanged style dependent on the shaft size. With the 104 style, shaft sizes of 1-1/2" or 2" will be fitted with a two-bolt flange and others with a three-bolt flange bearing.

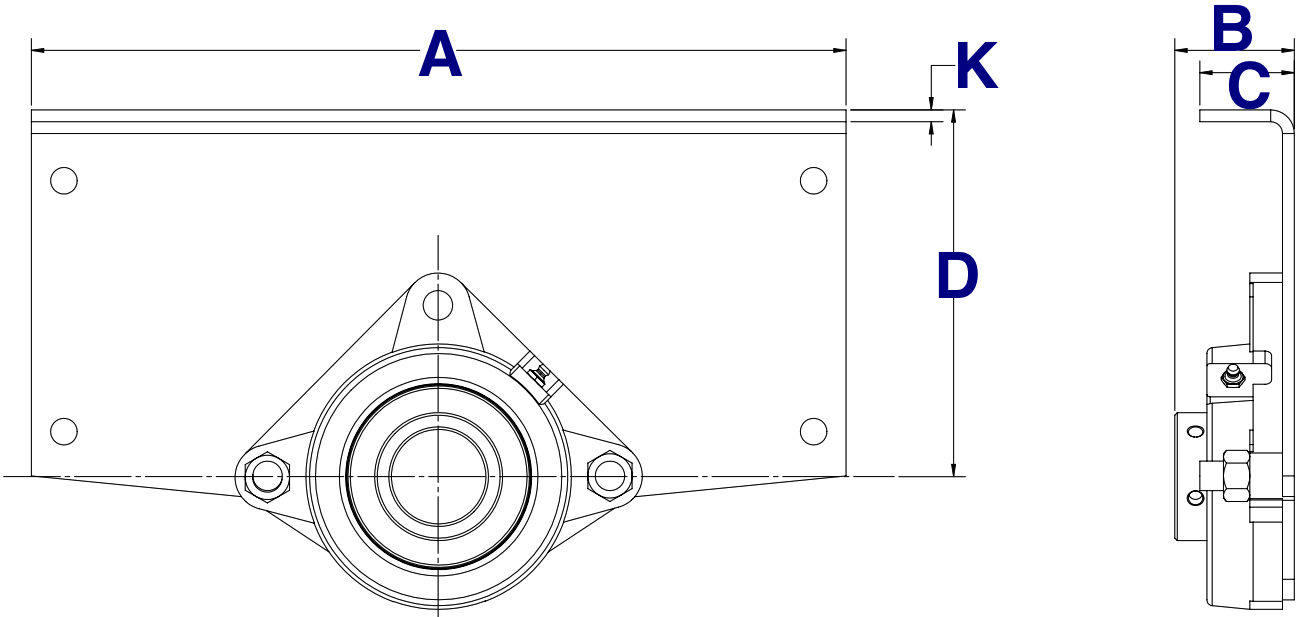

104 and 107 Discharge Trough End Dimensions

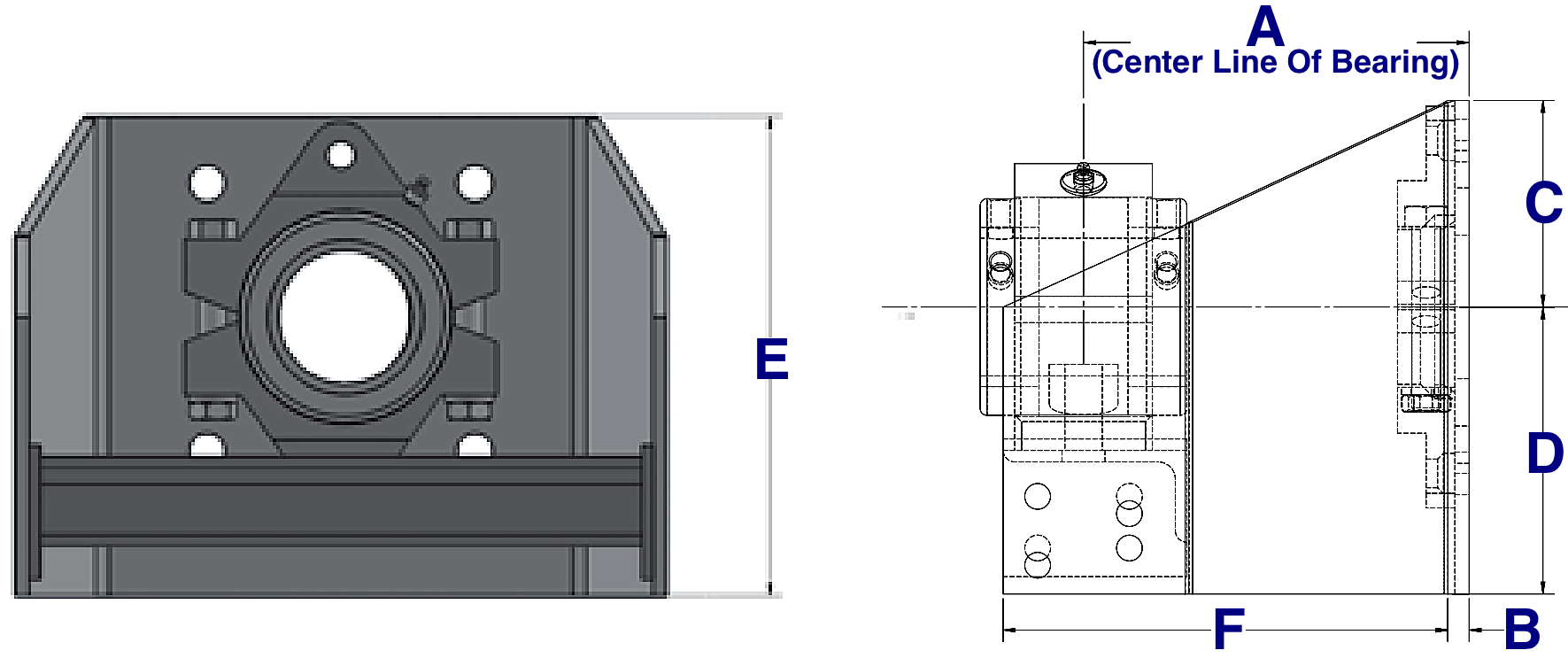

Style 114 and 115 Flared Trough Ends:

Styles 114 and 115 trough ends are considered flared trough ends because of their design. Flared trough ends are formed with a top flange that supports the screw conveyor cover and a cotton flange that serves the purposes of being feet. Its design fits the contour of a flared trough and can be fitted with babbitted flange bearings as well as anti-friction self-aligning ball bearings. They can also use flange bearings of bronze, Arguto wood, Nylon, Bronze Oilite, or any other conceivable bearing material based on the application's needs. The endplate of a flared trough end can also be fitted with a Chevron or Hammond end thrust bearing.

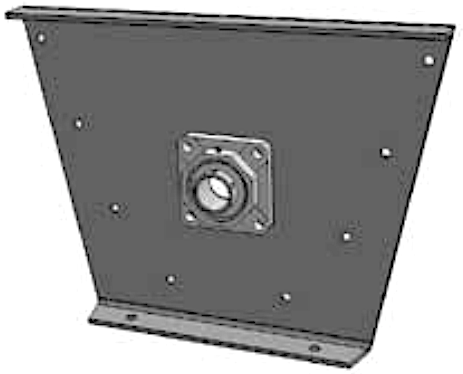

Style 114 and 115 Dimensions

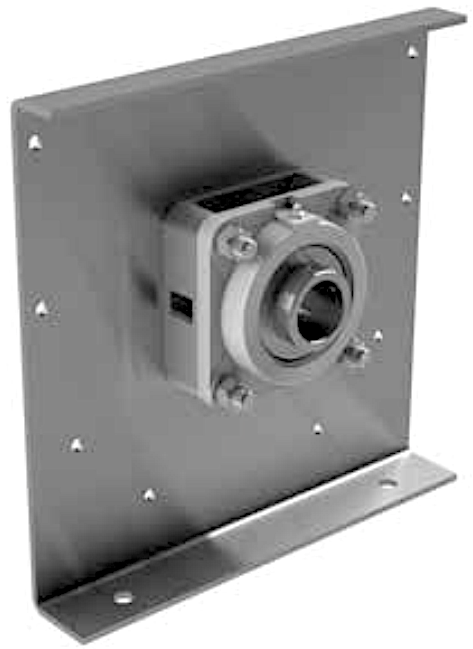

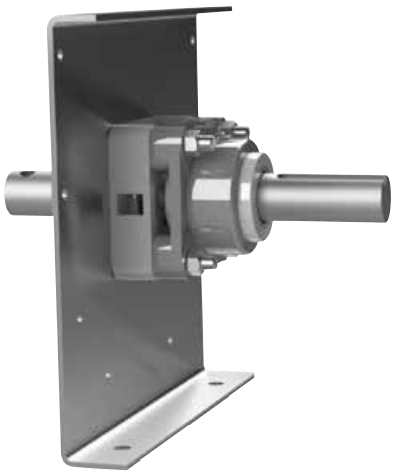

Bolt-On Shelf Trough Ends:

Bolt-on shelf trough ends are specially developed with bolt-on pump type seals to be adaptable to existing trough ends. This provides a cost-saving inventory reduction due to their interchangeability. The bolt-on shelf style trough ends allow for the outboard mounting of bearings which makes maintenance considerably easier. The shelf not only offers a solid mount for the bearing but provides stability for drives that include chain, v-belts, direct connect, or the use of a shaft mount reducer. The drive shaft between the bearing and seal is exposed, this makes the bearing run cooler resulting in an extended seal and bearing life. The bolt-on pump style seal is available in eight standard bore sizes and is also field adaptable on existing trough ends. This shelf offers maximum flexibility by being able to also use traditional split end seals and waste pack seals. Standardly these are made from high-quality steel but abrasion and corrosion resistant configurations can be supplied upon request.

Bolt-on Shelf Dimensions

CHEVRON Roller Bearing End Thrust With Trough End:

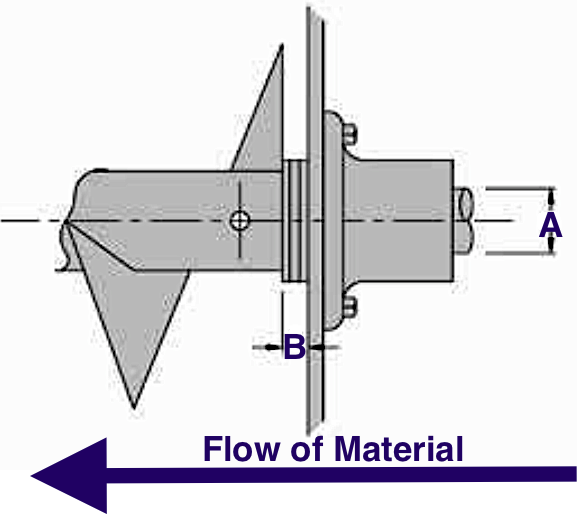

This trough end is equipped with a special roller bearing that is capable of handling medium to medium to heavy thrust and radial loads in either direction. When starting up a screw conveyor, the thrust load is created in the opposite direction of the material flow, and if the thrust load is not contained the hanger bearings, trough end, and screw all wear at an accelerated rate. The Chevron bearing assembly can be supplied with the drive or end shaft, it is always recommended that a screw conveyor is driven through this style of thrust unit rather than a self-aligning ball bearing.

CHEVRON Bearing Trough End Dimensions

HAMMOND Roller Bearing End Thrust With Trough End:

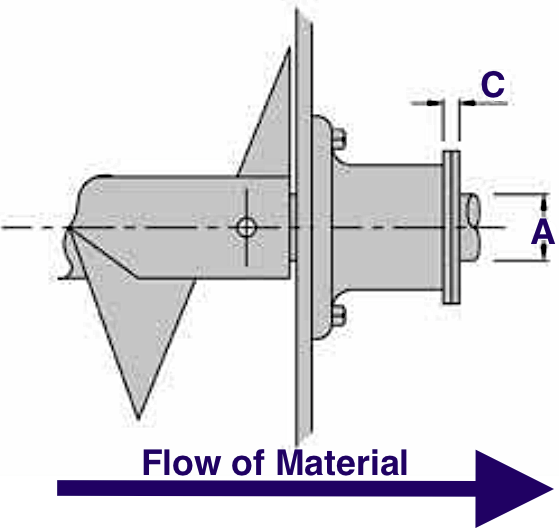

The Hammond bearing design is a dual tapered roller bearing end thrust that is capable of withstanding extra heavy thrust and radial loads in either direction. Although these bearings are typically mounted on steel plates you still need to specify the trough end when ordering because they are not automatically supplied.

HAMMOND Bearing Trough End Dimensions

Bronze Washer Type End Thrust

Type BW-1 Bronze Washer End Thrust:

This style is an inside style bronze washer end thrust that is mounted inside of the conveyor trough at the inlet end, it's an inexpensive assembly made to handle light to moderate compression thrust loads. The assembly consists of a transmission bronze washer flanged on each side by a machine steel washer.

Type BW-2 Bronze Washer End Thrust:

This style is mounted at the discharge end of the conveyor and is made to handle light tension thrust loads. The transmission bronze washer is held in place between the face trough end bearing hub, and a machined steel washer by a Tru-Arc thrust ring.

|

|