Proper lubrication is essential to a bearings life; not only does it extend the life of the bearing, but it also increases the unit's working life.

Pre-LubricationOur bearings come pre-lubed from the factory with 1/3rd grease filled with food-grade grease. Because they come from the factory already lubricated, you should not add grease to the unit until before placing it into service.

Relubrication

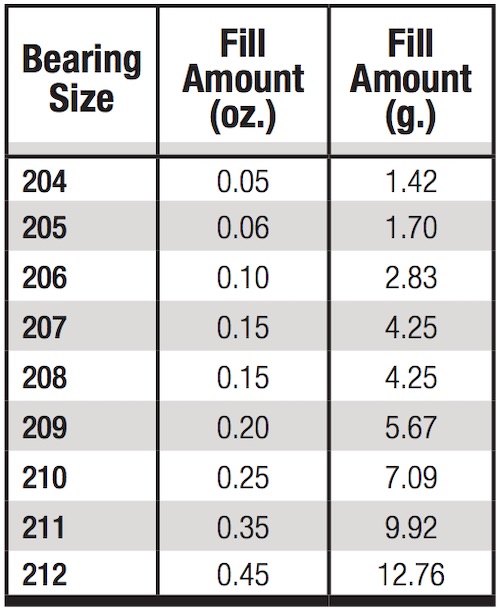

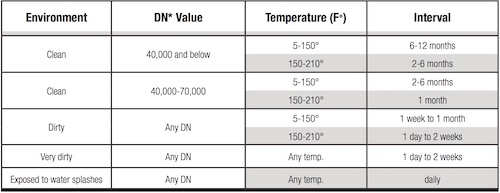

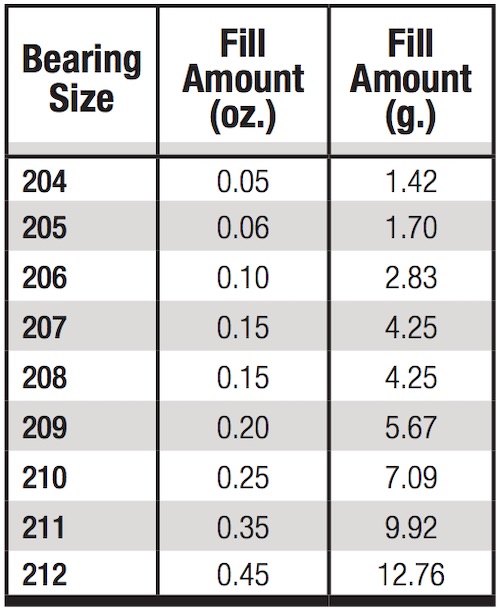

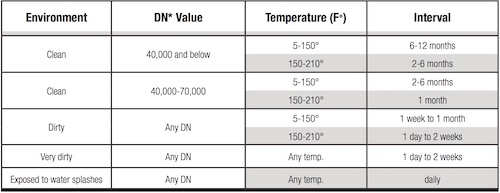

Relubrication can be more necessary in certain applications than others to maximize the lifespan of the bearings. In the relubrication process, only adding the grease listed in the above table is imperative to prevent over-filling the bearing. The ideal grease filling is 1/3rd at all times. If the bearing becomes overlubricated and fully filled with grease, it decreases the bearing's life and limits its speed. Do not relubricate a bearing with more lubricant than listed in the above table unless the bearing is in an extremely dirty, wet environment; avoid the common practice of pumping grease until you feel resistance or until lubricant is emitted from the bearing seal. Use the chart below for bearing relubrication intervals.

*= Bore of the bearing (mm) x RPM