Load Rating Data

The load rating table below is to be used as a general tool for determining how loads and speeds imposed on a bearing will affect the overall life of the bearing. By determining your expected radial load and speech, you can figure out the L10 life that will be suitable for your application.

Note: L10 hours are the number of service hours a bearing can be operated before 10% of the bearings fail. This means that the AVERAGE service life of a bearing (50% failure rate) will be higher than those listed below.

Note: Decreasing bearing loads will have an exponential effect of the fatigue life of a bearing.

The data below is based on radial load capacity for given life/speed (lbs.)

X = Past limiting speed for standard seal bearings

Bearing Fatigue Life

BEARING LIFE INFORMATION:

Fatigue

If a bearing is correctly mounted, lubricated, sealed from contaminants, installed properly, and handled accordingly, the only only other thing that can cause failure is fatigue of the material. Metal fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loadings.

Bearing Fatigue Life

The life of a bearing is defined as the hours of operation (at a constant speed) that the bearing is capable of running before evidence of fatigue develops in the material of the raceways or in the rolling elements of the bearing.

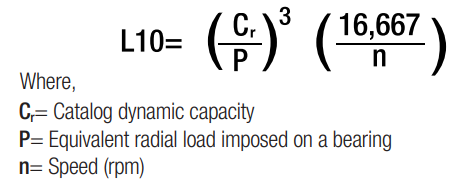

Calculating Bearing Life:

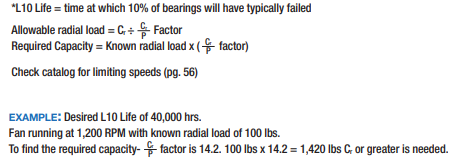

L10 is the number of hours (at a constant speed) that a group of bearings will run before 10% of the bearings fail.

Bearing life formula :

Note: The above formula assumes that the bearings are being ran in ideal operating conditions (including press-fit). Considering that typical mounted bearing applications have a flip fit, a derating factor multiplier should be used to calculate L10 life.

- For set screw and eccentric collar bearings, a multiplier of 0.456 should be used.

- For tru-loc bearings, a multiplier of 0.800 should be used.

Certain applications require different L10 life conditions. An application that is NOT used frequently will require lower L10 life hours to give sufficient performance than an application that IS frequently used and requires higher reliability.

L10 Life Chart

The data below is the Cr/P Factor for the stated RPM

Limiting Speed

The limiting speed of a bearing is greatly affected by the fit between the bearing bore and shaft. The values listed in the Limiting Speed Table below are based on ideal mounting conditions, which would include a press fit between the bearing and the shaft. For normal mounting conditions, like the shaft tolerances listed below, the listed maximum speed can be reduced by up to 25%. If your shaft does not fall into the listed tolerances, your maximum speed may be significantly lower than the listed speeds.

Limiting Speed Table

Troubleshooting Guide

If you have any additional questions or concerns, or if you need additional info about your specific application, please don't hesitate to contact us. One of our consultants will be happy to assist you in any way that we can!

|