Screw Conveyor Troughs

With over 200 standard troughs available plus custom or specially designed screw conveyor troughs, we have a trough for every bulk material handling screw conveyor application out there. A trough acts as the housing for a screw or screws dependent upon the length of the system and comes in an array of standard materials such as steel, abrasion-resistant steels, hot-dipped galvanized steel, and any other conceivable material that is required for the application at hand. Our standard troughs are the most commonly used U-trough but additional designs such as tubular housings and rectangular troughs are also available.

Types Of Screw Conveyor Troughs

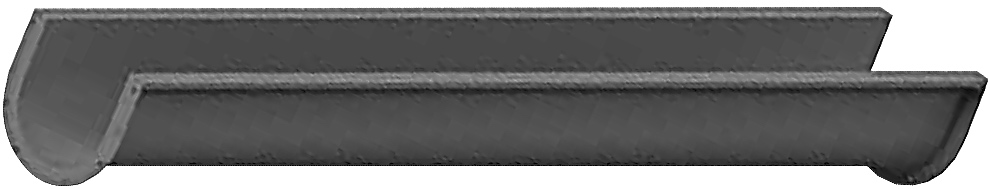

Double Flanged Trough

The double-flanged screw conveyor trough is one of the most commonly used troughs throughout the screw conveyor industry because of its highly functional and durable design. More specifically, the double flanges provide ample structural strength improvement as well as rigidity without adding additional weight, while also providing a platform for a dust-tight seal when paired with the Barron flanged cover. This style of a trough is available in sizes up to 24" and can be made in steel gauge thicknesses up to gauge 10. They can also be formed out of stainless steel or other material-specific needs that the application might require. Nu-Weld end flanges are continuously jig-welded on each end to assure alignment and tight connecting joints, and if supporting feet are needed they are spaced at the flange joints. We also supply trough saddles as well as all the necessary accessories needed for double-flanged troughs.

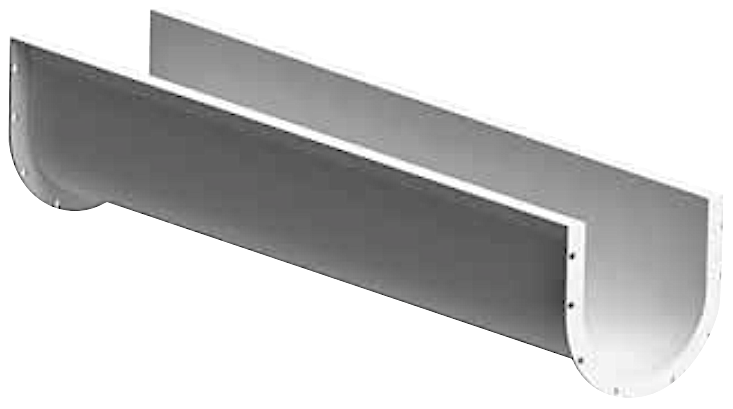

Angle Trough

Angel troughs are equipped with high-strength structural steel angels along the top edge of the trough to provide superior rigidity and strength across all trough sizes and gauge thicknesses. Nu-Weld end flanges are continuously jig-welded to each end to ensure alignment and tight connecting joints when installed. They can also be formed out of stainless steel or other material-specific needs that the application might require. Additional trough modifications such as a perforated bottom, a drop bottom for sanitary installations, jacketing for heating or cooling, and others are also available for angle troughs. Additionally, these are typically equipped with a Tite-Seal cover but we also offer additional cover types such as the dome flanged cover, hip roof cover, and others are available. We can also supply supporting feet that are mounted at the flange joints as well as trough saddles.

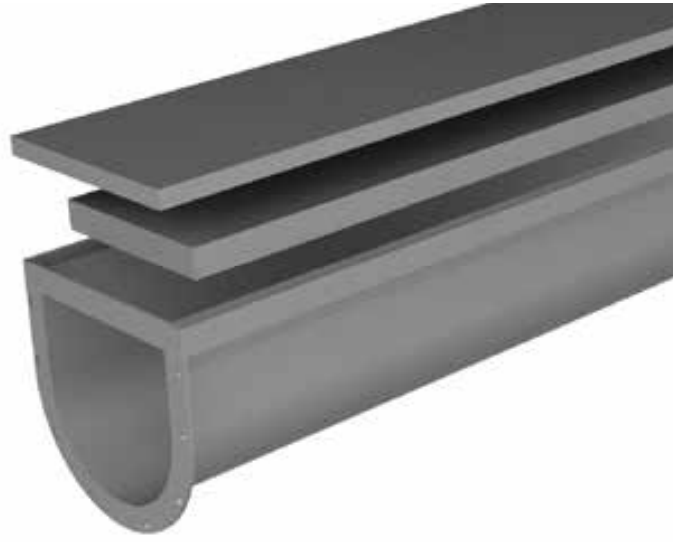

Flared Trough

Flared screw conveyor troughs are designed to allow the standard 1/2" clearance between the screw and the trough bottom. Utilization of the flared sides greatly improve the feeding and conveying action, particularly when conveying materials that are not entirely free-flowing, or materials in large slabs or pieces. The top edges are flanged to provide superior cover support and Nu-Weld steel end flanges are continuously jig-welded to each end to assure alignment and tight joints when installed. Besides standard steel, flared troughs can be furnished in stainless steel, Monel, or other alloys. Covers are usually bolted on or furnished with screw or spring clamps and can be flat for interior or hip roof for exterior applications. We also stock a wide array of flared trough ends as well as other screw conveyor parts.

Channel Trough

The specially designed channel trough is made with a separate rolled or formed steel bottom for use where severe abrasion or corrosion factors require frequent trough replacements. The bottom is bolted to the structural steel side channels making a very rigid unit that can be used where trough supports are necessarily widely spaced.

Dust Seal Trough

Dust seal troughs are formed with special Z-bars along the topsides and channels across the top width. This forms a continuous pocket into which the flange cover fits. This pocket can then be filled with sand, sponge rubber, or the material being conveyed to provide a dust-tight seal that will allow quick access to the trough interior.

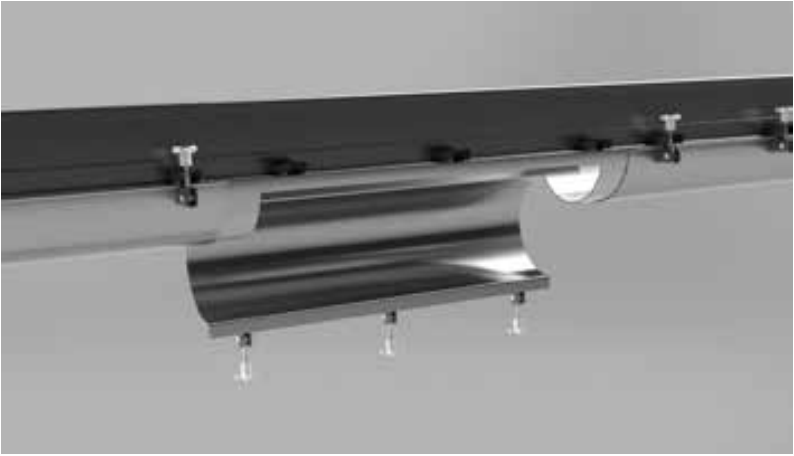

Tite-Seal Drop Bottom Trough

Gaining quick access to the screw conveyor and trough can be a daunting task at hand unless you have one of these specially designed drop-bottom troughs. The drop bottom trough gives you almost instant access to the screw conveyor. It works by having a hinged bottom section that swings open when the clamps are disengaged. The edges of the opening are gasketed to seal when closed. The trough can be equipped with a single flange or be double-flanged and can be fitted with any choice of cover.

Tite-Seal Drop Bottom Trough Information:

- The hinge side and latch are adjustable to secure the seal.

- Product pressure points are reinforced to prevent leakage.

- Drop bottom fits standard troughs of 10-gauge and heavier.

Jacketed Trough

The jacketed troughs are designed to carry an agent for heating, cooling, or drying of material while it is being conveyed. A former jacket is continuously welded to a standard trough or a trough built to specific standards. It is important to note that jacketed troughs are not designed or constructed to be pressure vessels.

Screw Conveyor Trough Dimensions

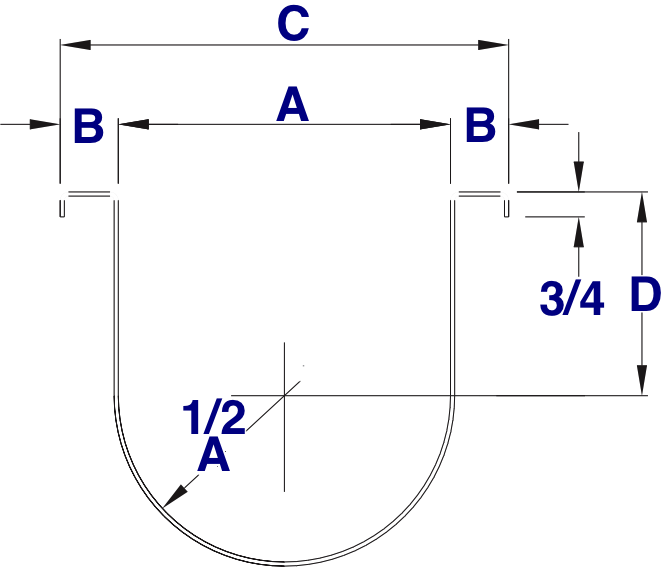

Double Flanged Trough Dimensions

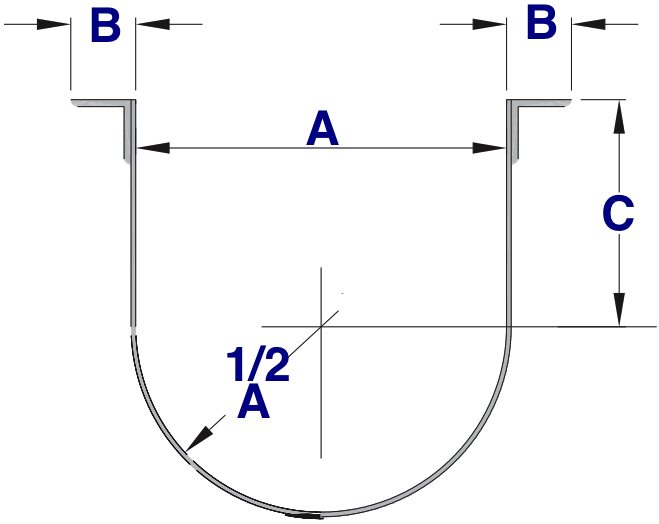

Angel Trough Dimensions

Flared Trough End Dimensions

|

|