|

Jump to the Top

#60 Roller Chain Applications

The #60 roller chain can be found in a broad range of applications, including light- to heavy-duty industrial grade. With a relatively small form factor and high payload capacities, a size #60 roller chain can be used within a wide range of applications.

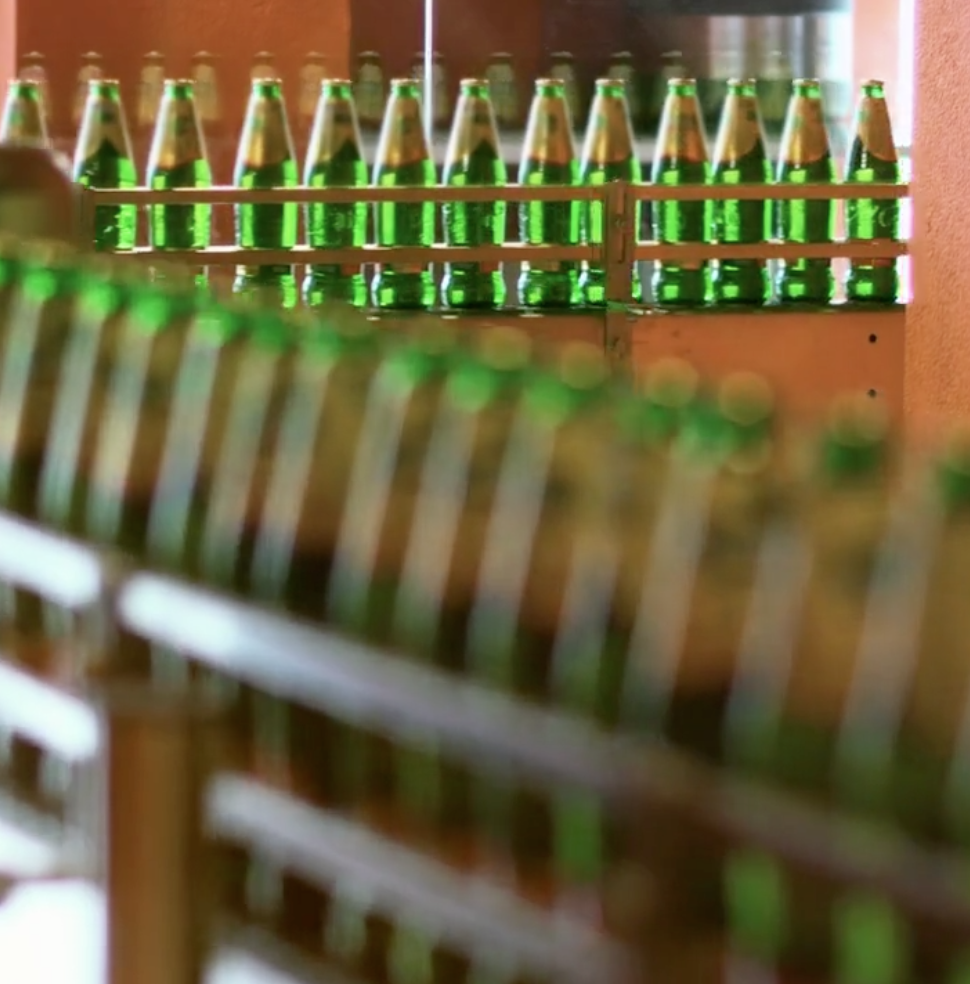

Bottling and Packaging:

The 60 roller chain is often used in bottling and packaging facilities as part of equipment drive systems. Side-bow and 63-size chains are also used as "base chains" for table-top-style chains within bottling facilities.

Live-Roller Conveyors:

The 60 chain is often used on live roller conveyors and beds. The chains are used not only as the main drive in the system but also for transferring the energy from one sprocket to the next. These conveyors work by utilizing double-strand sprockets to essentially daisy-chain the transfer of energy, as the 60 chain turns the sprockets the live rollers move in the opposite direction, creating a live roller that transfers products across the top.

Agricultural Equipment:

The 60 roller chain is used in agricultural equipment of all types, such as corn head gatherers, hay bale elevators, cotton harvesters, grain harvesting equipment, live bottom trailers, and more! The ability for a 60 chain to run at high RPMs consistently while efficiently transmitting energy makes it a great pair for agricultural equipment applications. Because of its popularity in agricultural uses, finding quality 60 roller chain strength is crucial. Farmers rely on their equipment to work properly, day in and day out, so making sure you have a quality chain is key to avoid any disruptions in the field.

Conveying Applications:

ANSI 60 chains are found in many general conveying applications, even though the chain is designed as a transmission drive chain. This is due to its high-strength capabilities and ease of maintenance. We offer straight side-bar-style 60 chains to increase the conveying surface area capabilities. These chains are typically classified as either having a "C" in front of the 60 or as having an "F" placed after the #60. The F-type 60 chain is also designed for use in conveying applications. It has the same strength and durability as the C type, but with the addition of flat top plates. This gives the chain a larger surface area that can be used for carrying heavier loads.

Drive Applications:

The 60 roller chain is a strong, durable chain that is designed for use in a variety of applications. It is commonly used in chain drive applications, such as aggregate, mining, construction, mixing, and even dryer applications. We also offer a Super 60 roller chain for extreme-duty applications, as well as an API-certified cottered 60 chain for oil and gas applications. Our 60 roller chain is made from high-quality materials and is built to last.

Jump to the Top

We supply 60 roller chains on bulk reel roller chain sizes such as 50-ft and 100-ft reels. This can often be preferred when "cutting" a large amount of shorter-length chains or with long-length runs of 60 chains. We stock bulk reels in standard carbon steel, stainless steel, and nickel-plated materials, and we have bulk coated and cottered 60 chains.

USA Roller Chain is your partner in drive solutions. After the identification process is complete, our team works to keep you informed throughout the manufacturing process. We strive to make the process as simplistic and smooth as possible. Our custom roller chain manufacturing process requires a minimum of 200 feet, and it can take anywhere from six weeks to 16 weeks, depending on whether expedited services are required and current scheduling capabilities. We supply anticorrosive and abrasion-resistant 304- to 316-grade stainless steel options, as well as nickel and standard carbon steel.

It's important to understand the base parts of the 60 roller chain and what each component is and does. This knowledge is handy when it comes to inspecting chains during routine maintenance.

60 Chain Pin:

Pins are 0.234" in diameter per the ANSI B29.1 spec for 60 chains and handle a portion of brunt shock and working loads transferred from the side plates. When inspecting an active roller chain, it is important to notate any cracking, deforming, or pin roll, as any of these three symptoms can indicate a need for chain replacement.

60 Chain Bushing:

Bushings within a roller chain are placed between the pin and roller. Their purpose is to facilitate the transfer of energy throughout the chain and be a bearing surface within the roller. We offer our 60 roller chains with optional split or solid bushings; solid bushings provide a superior chain working life versus split bushings.

60 Chain Roller:

The rollers for 60 roller chains are 0.469" in diameter and are a solid construction. Their job is to effectively roll within the sprocket tooth root to facilitate the transmission of energy. To ensure peak performance from your 60 roller chain, it is important to inspect the rollers regularly. Look for any deformation, cracking, or excessive wear. If you see any of these signs, it's time to replace the sprockets and/or chain.

60

Chain Side-Plates:

The dimensions of a standard side plate for an ANSI 60 roller chain are 0.093" thick, while the dimensions of a heavy-duty 60 side plate are 0.125" thick. Side plates serve an important purpose in roller chains by absorbing the majority of the working and shock loads placed on the chain while it is in motion. Depending on the application, 60 roller chains are available with standard side plates, wide-waist side plates, or even straight side plates.

Jump to the Top

|