DUROCHAIN - Premium Roller Chain

A peak performance precision roller chain made specifically for the roughest toughest industrial applications out there; that's what we at USA Roller Chain & Sprockets team had in mind when we came up with our very own DUROCHAIN® brand of roller chain. As one of the nation's largest roller chain distributors, we collectively made the decision to go past the "industry standard" and design a new series of roller chain that not only exceeds in true performance but is also sold at a price-point for customers of all types to have access to. We created this new series of roller chains with three principles in mind;

• better design • better materials • better performance, which as a family-based and operated company we feel we delivered these principles, and then some!

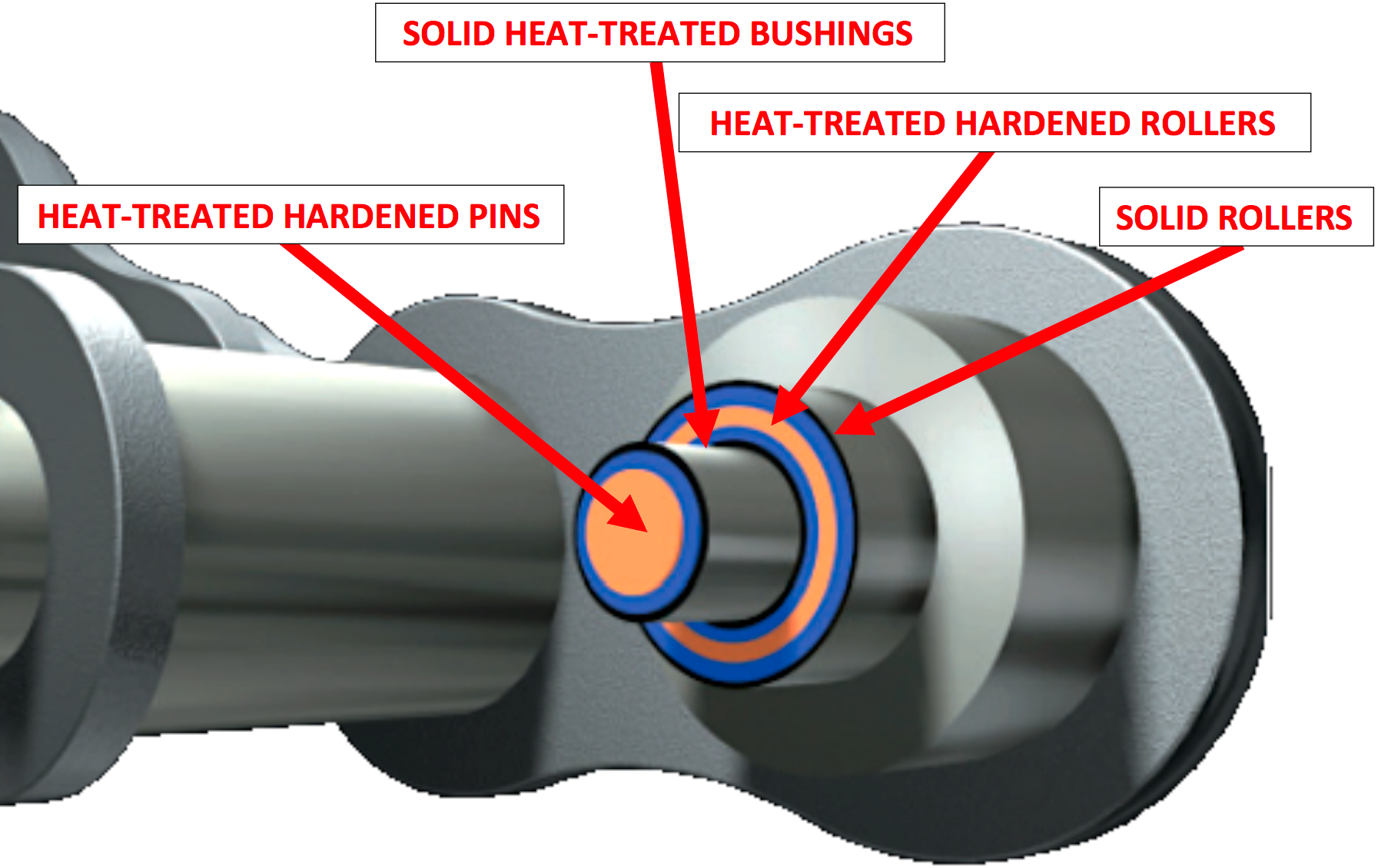

Solid Bushings and Rollers

The utilization of a sold bushing and solid roller internal design makes for a roller chain that can handle the long-term fast-pace needs of a roller chain. Bushings are in a complete 360° contact with the pins, meaning that a sold/ seamless design provides a complete 360° wear surface. While at the same time, the roller is in 360° contact with the sprocket teeth and deflect the blunt force of a chain as it comes into contact with sprockets. Besides the up-front obvious wear improvements, a split bushing and or roller will give and separate under load over time, creating two surfaces within the chain where friction, as well as wear, become prevalent and eventually lead to premature failure as well as increased drive energy consumption.

Wide Waist Link Plates

Link-plates are what holds a roller chain together and put up with the majority of the overall shock load with a chain. Our chains are even supplied with this syle link plate on the inside and outside plates! Using a wide-waist link plate in rue of the "standard" not only improves shock load and tensile strength capacities but also improves the overall rigidity of a roller chain. In lifting and conveying applications alike a wide-waist link plate proves an improved shock load factor versus roller chains that do not utilize wide-waist link plates.

Quad Staked Rivets

In almost every application, a roller chain will experience side-load of some sort either from something as simple as a sprocket misalignment of even failure of additional components within the system. Side shock loads can and will reak havoc on a chain and can even cause catastrophic failure, this is why we quat-staked our rivets versus the standard double-staked rivet. Quad steaking rivets provide double the holding power of the "standard" rivets and even in the event of extreme side shock load, the chain has twice as many rivets to depend on and twice the available side capacity.

Double Punched Holes

A smooth surface between the link plates and the pin is essential with a roller chain to reduce "pin-roll" which not only off-centers a pin but also creates internal wear and tear on the plates and pins resulting in reduced life of a chain. Double punching the link plates creates a super-smooth surface to ensure maximum correct contact between the pin and plate. This additional contact creates additional holding power, thus diminishing most of the "pin roll" issues present in standard roller chains.

Shot-Peened Components

The sheer act of shot peening a roller chain increases the overall chain fatigue resistance, but with our special proven and consistent shot-peening process, our chains fully take advantage of the process. We utilize a material of high quality to shot peen our chains, resulting in an even further increase of fatigue resistance versus other chains.

Pre-Stretched

Elongation is one of the most common issues with a newly installed chain, this is why we pre-stretch/ pre-load all of our DUROCHAIN® roller chains to prevent and even eliminate this elongation upfront and throughout the overall life of the roller chain. Preloading reduces distortion within the chains operating life and even reduces component material noise through the operating life of the chain.

Premium Factory Supplied Lubrication

Proper lubrication/ oiling of a roller chain is just as essential as grease is to a bearing, the amount of metal-to-metal contact in a roller chain justifies consistent and proper lubrication. The DUROCHAIN® roller chains are automatically supplied with a premium quality lubricant that ensures low-friction and excellent performance.

|

|

|