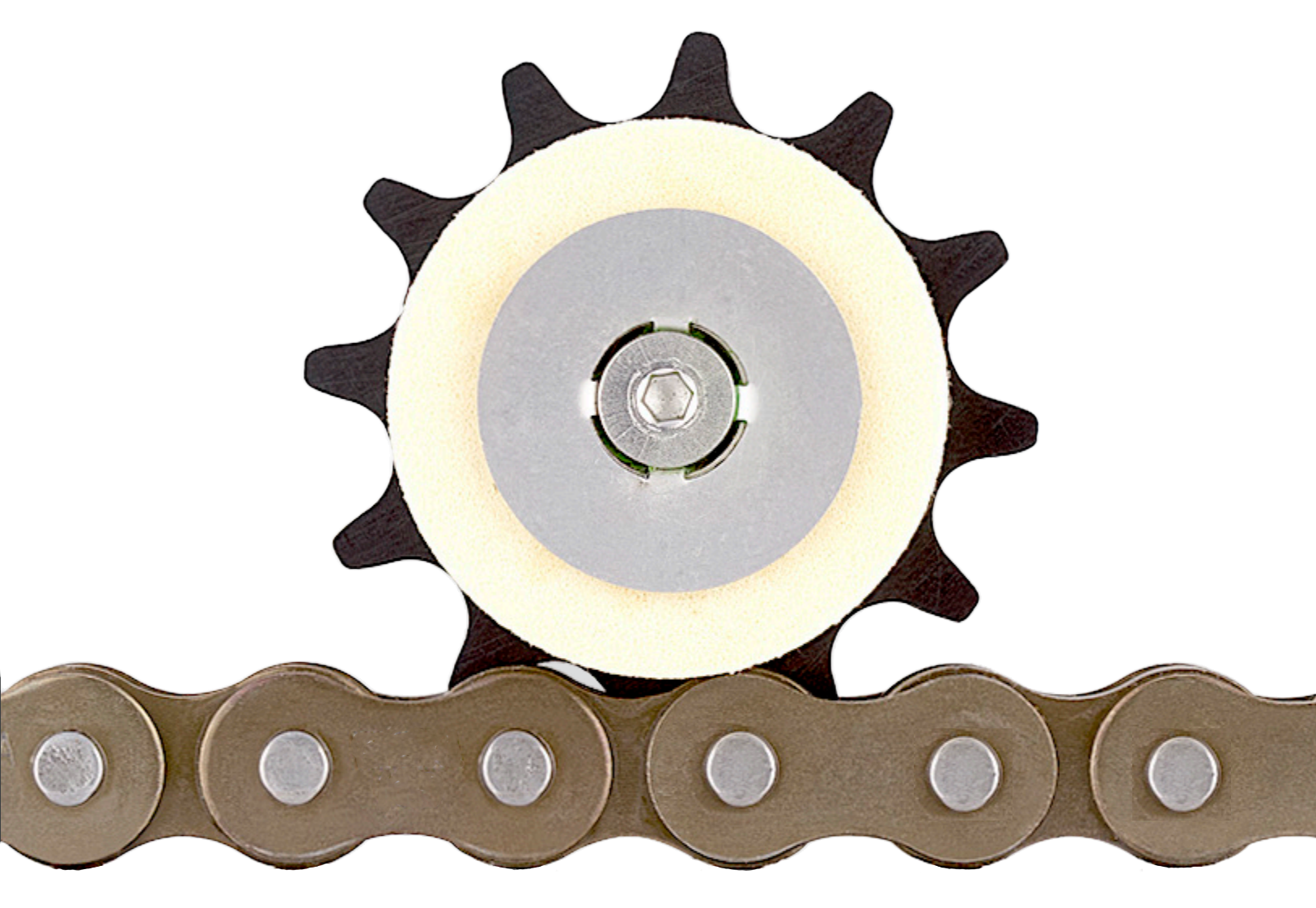

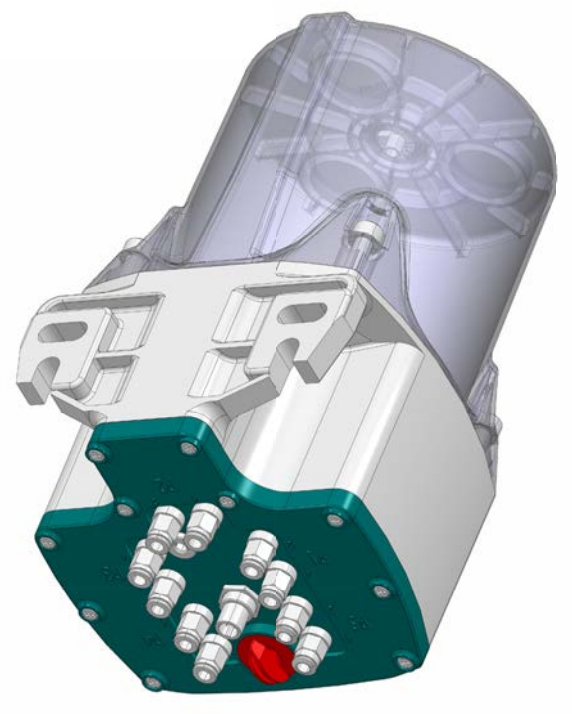

There is a vast selection in the world of automatic roller chain lubricators. However, it is nothing quite like the one we supply. This unique lubricator utilizes a high-tech programmable pump that dispenses the lubricating into a specially manufactured applicator that precisely lubricates the roller chain without drippage. Unlike others, these highly versatile lubricators are customizable for engineer class chains such as; 81X WH78, WH124, 94R, CC5, etc..

orem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.