J-Series Hydraulic Motors

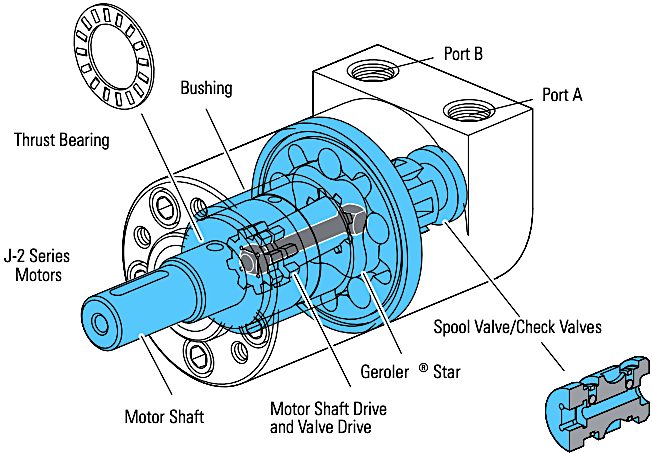

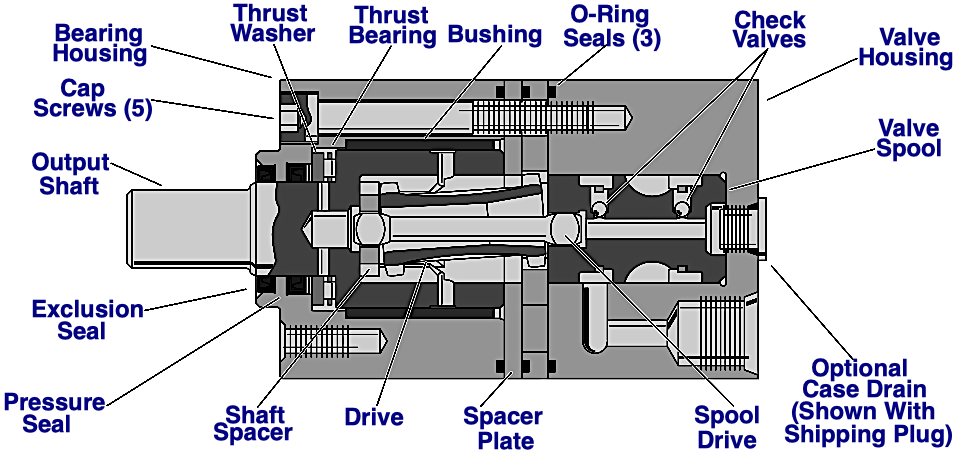

J-Series hydraulic motors are manufactured for smaller form-factor or limited space applications, although in a small package, J-series hydraulic motors provide a lot of power. Our J-Series motors are able to handle up to 5 KW (6.5 HP) of power. This series is only 61mm (2.4") in diameter and 104mm - 130mm (4.1" to 5.1") in length. The special seals and shaft supplied in these hydraulic motors make them capable of handling a case pressure of up to 76 bar (1100 PSI) return line pressure without a case drain line. In circumstances where there is a case drain line, the maximum/ peak allowable return line pressure is 220 bar (3190 PSI). Our J-Series motors have the benefits of being high-efficiency motors with a long-term leaf-free working life all within a flexibly designed powerful and compact package. Common applications for these motors include; agricultural equipment, car wash sprayers and brushes, marine bow thrusters, food processing equipment, railroad equipment, machine tools, conveyor systems, snow blowers, sweeper, polishers, turf reel drives, lumber mill machinery, paint strippers, and more! These hydraulic motors interchange with popular brands such as; Charlynn, White, Ross, Parker, TRW, Danfoss, and Young Power Tech. We utilize other manufactures part numbering systems for ease of interchange purposes. For additional information or to get a quote on our J-Series hydraulic motors contact our customer service team and we will be happy to assist you.

Note Note - The maximum pressure at the motors inlet port is 220 Bar (3190 PSI) without regard to ∆ bar [∆ PSI] and/ or backpressure ratings or a combination thereof. ∆ Pressure - The true ∆ bar (∆ PSI) difference between the inlet port and outlet port. See individual shafts for maximum torque recommendation. Splined shafts are recommended for those applications subject to frequent reversals.

Continuous Rating - The J-Series hydraulic motor can be run continuously at the ratings in the chart below.

Intermittent Operation - 10% of Every Minute.

Peak Operation - 1% of Every Minute.

Recommended Fluids - With J-Series motors it is recommended to use premium quality, anti-wear type hydraulic oil with a viscosity no less than 70 SUS at operating temperature.

Recommended System Operating Temperature - minus 34°C up to plus 81°C (-30°F - +180°F).

Recommended Filtration - Per ISO Cleanliness Code 4406, Level 20/18/13.

Specification Data Chart:

J-Series Hydraulic Motor Product Numbers

End Port Sizes:

Displ. cm^3/r (in^3/r)/ Product Number

*Note: The Same Casting Used For Side Ports is Required for G 3/8(BSP) End Ports

Side Port Sizes:

Displ. cm^3/r (in^3/r)/ Product Number

- Two Bolt Mounting Flange Kit (for 3/8" Mounting Bolts) - Kit # 60552 (Includes 5 Screws - 1/4-28 UNF-2B)

- Two Bolt Mounting Flange Kit (for M8 Mounting Bolts) - Kit # 60553 (Includes 5 Screws - M6 X 1-6H)

Note: These part#s are a common interchange for our hydraulic motor, actual part # will be different.

|

|