H-Series Hydraulic Motors

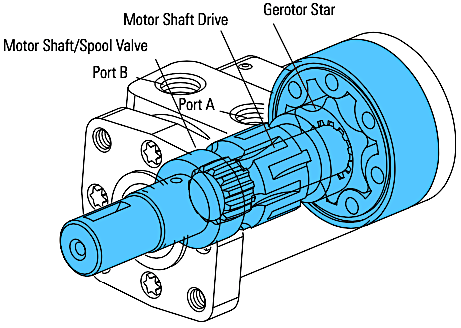

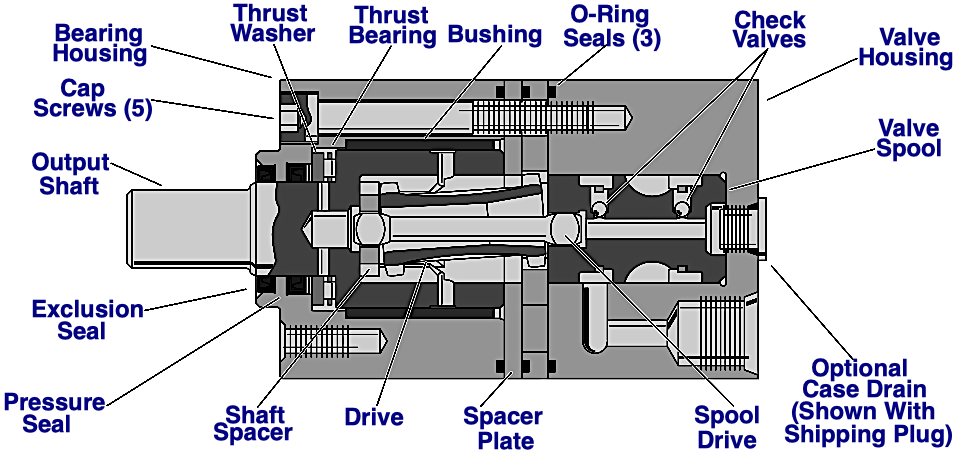

H-Series hydraulic motors are manufactured and designed for medium-duty applications. H hydraulic motors utilize the industry proved spool valve technology in combination with state of the are gerotors. H-series hydraulic motors also have great flexibility with applications due to the many mounting flanges, shafts, ports and valving options available. The shaft directions can be adjusted seamlessly throughout the speed range of the motor. Equipment can be direct driven to eliminate the cost of mechanical components. The high efficiency in a compact and flexible design makes H-series motors the main choice for many applications such as; agricultural equipment, car wash brushes, food processing, railroad equipment, machine tools, conveyors, sweepers, mills, turf equipment, concrete equipment, skid steers, and more! These hydraulic motors interchange with popular brands such as; Charlynn, White, Ross, Parker, TRW, Danfoss, and Young Power Tech. We utilize other manufactures part numbering systems for ease of interchange purposes. For additional information or to get a quote on our H-Series hydraulic motors contact our customer service team and we will be happy to assist you.

Gerotor Element - Gerotor Element - 13 Displacements Flow I/min (GPM) - 57 (15) Continous / 76 (20) Intermittent Speed - Up To 1100 RPM Pressure - 125 BAR (1800 PSI) Continous / 165 BAR (2400 PSI) Intermittent Torque - 407 Nm (3604 lb-in) Continous / 520 Nm (4600) Intermittent, 6B Splined or tapeed shafts are reccomended whenever operation above 282 Nm (2500 lb-in) of torque, especoally for those applications subject to frequent reversals. Note - The maximum pressure at the motors inlet port is 172 Bar (2500 PSI) without regard to ∆ bar [∆ PSI] and/ or backpressure ratings or a combination thereof. ∆ Pressure - The true ∆ bar (∆ PSI) difference between the inlet port and outlet port. See individual shafts for maximum torque recommendation. Splined shafts are recommended for those applications subject to frequent reversals.

Continuous Rating - The H-Series hydraulic motor can be run continuously at the ratings in the chart below.

Intermittent Operation - 10% of Every Minute.

Recommended Fluids - With H-Series motors it is recommended to use premium quality, anti-wear type hydraulic oil with a viscosity (at operating temperature) that should be the highest of the following 100 SUS or: [300 x Bar/RPM = SUS] or [20 x PSI/ RPM = SUS].

Recommended System Operating Temperature - minus 34°C up to plus 82°C (-30°F - +180°F).

Recommended Filtration - Per ISO Cleanliness Code 4406, Level 20/18/13.

Specification Data Chart:

J-Series Hydraulic Motor Product Numbers

End Port Sizes:

Displ. cm^3/r (in^3/r)/ Product Number

*Note: The Same Casting Used For Side Ports is Required for G 3/8(BSP) End Ports

Side Port Sizes:

Displ. cm^3/r (in^3/r)/ Product Number

- Two Bolt Mounting Flange Kit (for 3/8" Mounting Bolts) - Kit # 60552 (Includes 5 Screws - 1/4-28 UNF-2B)

- Two Bolt Mounting Flange Kit (for M8 Mounting Bolts) - Kit # 60553 (Includes 5 Screws - M6 X 1-6H)

Note: These part#s are a common interchange for our hydraulic motor, actual part # will be different.

|

|

|